VR-ROLLER

PREMIUM & HIGH PERFORMANCE COMPACTION ROLLER

VR-ROLLER - Premium Series

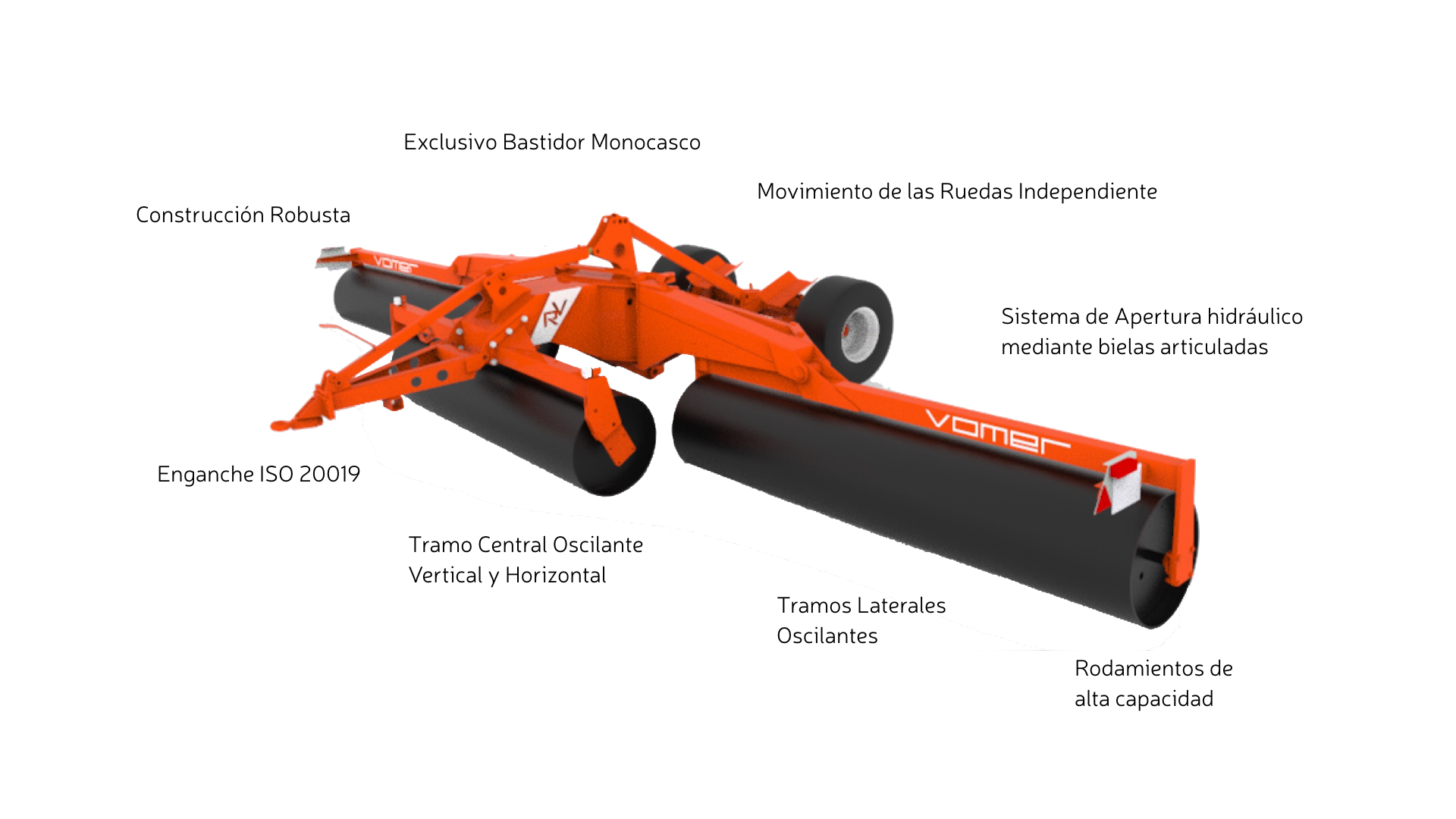

The compaction roller Vomer VR is the perfect tool for the final preparation of the soil. The VR offers a consolidated surface, free from furrows, blocks of soil or bumps, typical from tilling, which makes it ideal for sowing tasks. It is also used for compaction labor so that it preserves the humidity of the terrain, both before and after sowing. Exclusive characteristics such as the Monocasco chassis or the Opening/Closing system with articulated connecting rods makes the VR the leading model of these type of equipments. The carefully designed weight distribution and the oscillating parts guarantee a homogeneous and equillibrated track. A robust and realiable model.

THE PACKER ROLLER

The roller has been traditionally used to compact and consolidate the terrain making the seed have a good contact with the soil, and the optimal conditions for growing. Moreover, the roller allows to cover the rocks, so that it doesn’t cause problems to the seeders. However, the rollers can make much more than this, because with the right equipment they can work as surface sowers, breaking the superficial crust and leveling the furrows of previous works.

Ground cultivation with the roller

Breaking of soil blocks and levelling of the ground after previous works are two of the main tasks of the roller. If additional compaction or consolidation is needed, Vomer had three models with greater weigh by meter. Dragging a Cambridge smooth or raptor Vomer roller combines both efficient levelling and cultivation, equally important on spring or autumn.

Vomer Cambridge models also give the roller the capability of self-cleaning, which makes it usable when the soil is humid and loose, or after working with discs or the sower.

Breaking of superficial crust

When periods of rain come between the sowing and germination of the seed, a superficial crust is built that could completely compromise the cultivation, same process as in winter frosts. In those circumstances it is necessary to act against that crust, with a tool that is capable of breaking it without damaging the crops. The use of the Cambridge Vomer roller could be the solution to that problem. When the crust is harder, the VR-ROLLER Vomer Raptor will be the more efficient equipment. Thanks to the extra weight and the more aggressive profile these breaking of the crust will be efficient.

Roller used in spring after the sowing

Vomer rollers used after sowing create optimal conditions for the germination of the seed. The rocks are pushed down and the ground surface is uniform.

Roller used in spring for autumn cultivations

The winter frosts on crops cultivated on autumn have the ability of creating a superficial crust, which reduces the contact between the roots and the surface. Vomer Cambridge or Raptor rollers compact the terrain, breaking the crust and allowing the contact between the root and the surface for optimal development.

Roller used on oleaginous seeds in spring and colza in autumn

Vomer Roller used after sowing guarantee that the oleaginous and colza seeds have a better contact with the soil, allowing after just one passing one of the best conditions for germination of said seeds.

MODELS RANGE

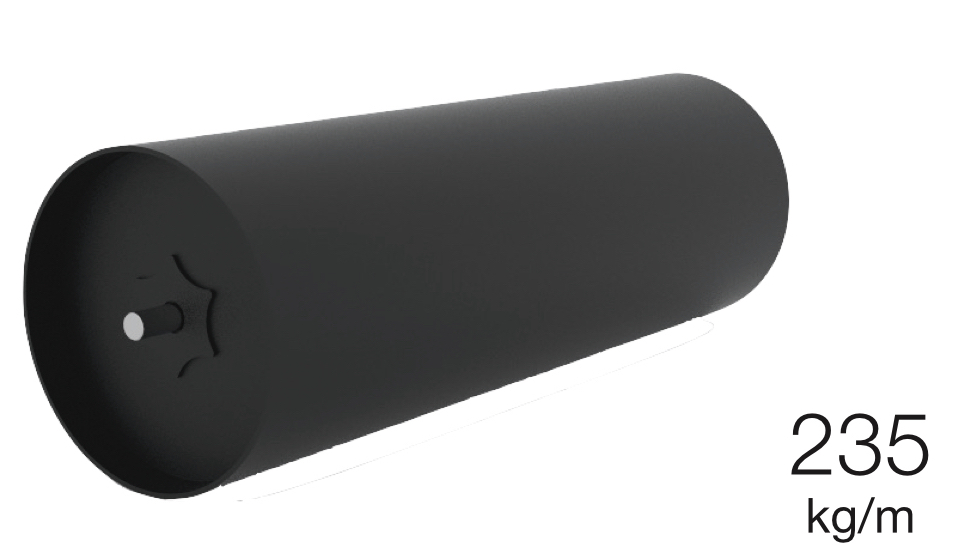

FLAT 650

The flat road roller in Ø650 is used for growing crops, after the sowing of the alfalfa, fodder and cereal, and its also used in other labour during autumn or spring. As it doesn’t have the cultivation capability, this type of roller is highly appropriate for rock terrains, as their smooth surface covers the rocks and decreases the risk of damages.

This type of rollers offers the possibility of changing the total weight allowing the filling of the internal part of water (up to 1/3). The tube is built on high durability steel in 12mm thickness, with an axis of Ø60mm (Ø70mm from10,00m) and wheel on oscillating bearings of high capacity.

*Cleaning elements are optional for this type of roller.

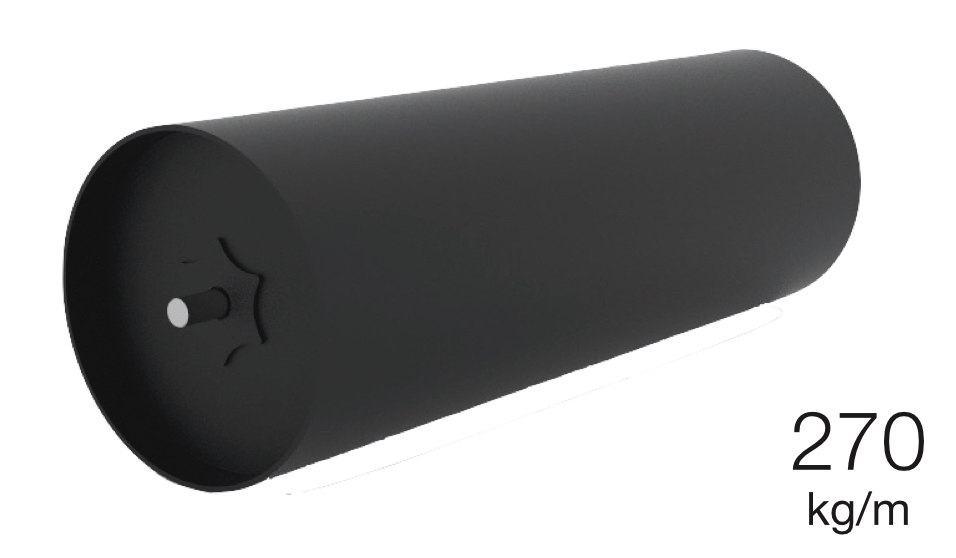

FLAT 750

The flat road roller is used for compaction of light terrain where there needs to be a more thorough cover of rocks. These flat road rollers in Ø750 have a higher rolling capacity, translated in a substantial decrease of dragging effect and a decrease on fuel consumption.

*Cleaning elements are optional for this type of roller.

FLAT 650/750 + RINGS

The compactor tube with rings is designed for a consolidation and compaction effect, and at the same time leaving small furrows on the surface. These small furrows help to locate rain water, and even avoid its sliding. The rings help breaking the superficial scab, after the grower or after the sowing.

The 20mm diameter rings, are located uniformly at a distance of between 20 and 25cm depending on the model.

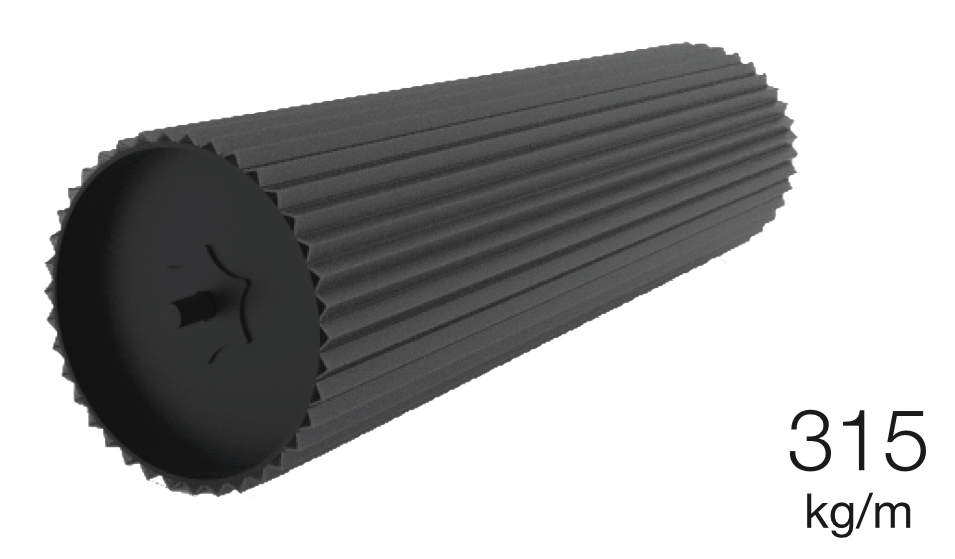

RAPTOR 750

Compactor roller with flat tube in Ø650mm and a longitudinal groove of angular type. With external diameter of 750mm, this roller is suitable for heavy consolidation and cultivation tasks. The aggressive profile is optimal for breaking and movement of the superficial terrain, and it merely damages the plant when it is used after the cultivation process. As the weight is superior to all the other models of flat tube, it is also recommended for extra consolidation labour

VR-ROLLER TECHNOLOGY

In every reconsolidation works it is important that all the terrain receives teh same compaction effort so that all have the same growth condition. To achieve this, the Vomer VR.ROLLER has been designed with a weight distribution that has oscillating parts and guarantees optimal adaptation to the terrain.

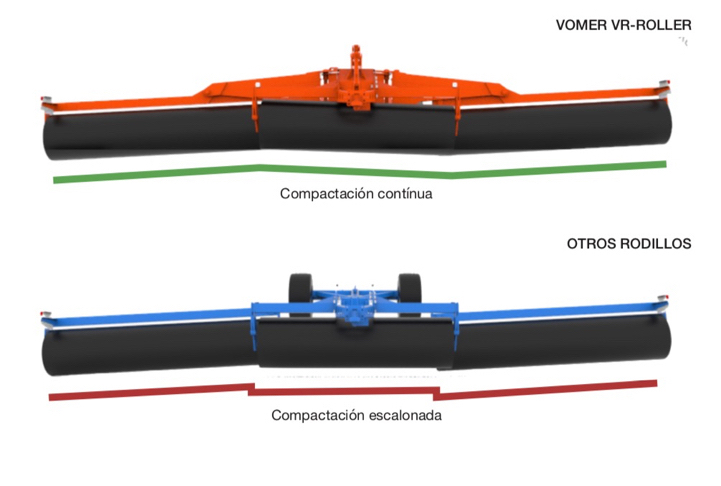

OSCILANTING SYSTEM

The roller is divided in 3 sections, which oscillate independently. This configuration achieves a continuous compaction, avoiding the scalling of other systems. The lateral sections incorporate a horizontal oscillating axis displaced from the central position. The central section oscillates vertically and horizontally, which guarantees the best contact with the terrain and avoids possible dragging.

All the elements of the system are manufactured in high durability steel and require low maintenance.

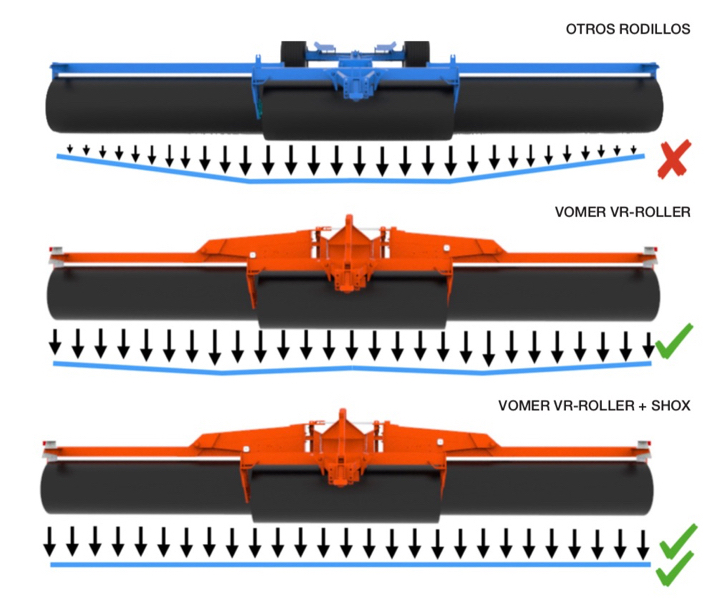

WEIGHT DISTRIBUTION

As indicated, a homogeneous consolidation is fundamental for the growing conditions of all plants, that is why the design of the VR-ROLLER is focused on a good distribution to make uniform pressure on the terrain.

In an analysis of the rollers with hydraulic opening, a V weight distribution is obtained, where the central area supports the majority of the weight, so it over-consolidates in that area increasing also the dragging risk.

The main problem lies in distributing all the weight on the chassis, the wheels and other elements, on the terrain in a homogeneous manner.

Even more, our exclusive SHOX* system makes it for the ideal weight distribution, completely plain.

Español

Español English

English Français

Français Русский

Русский Українська

Українська